TIG welding has some advantages over other welds, such as MIG welding. This article will tell you about are 3 advantages of TIG welding?

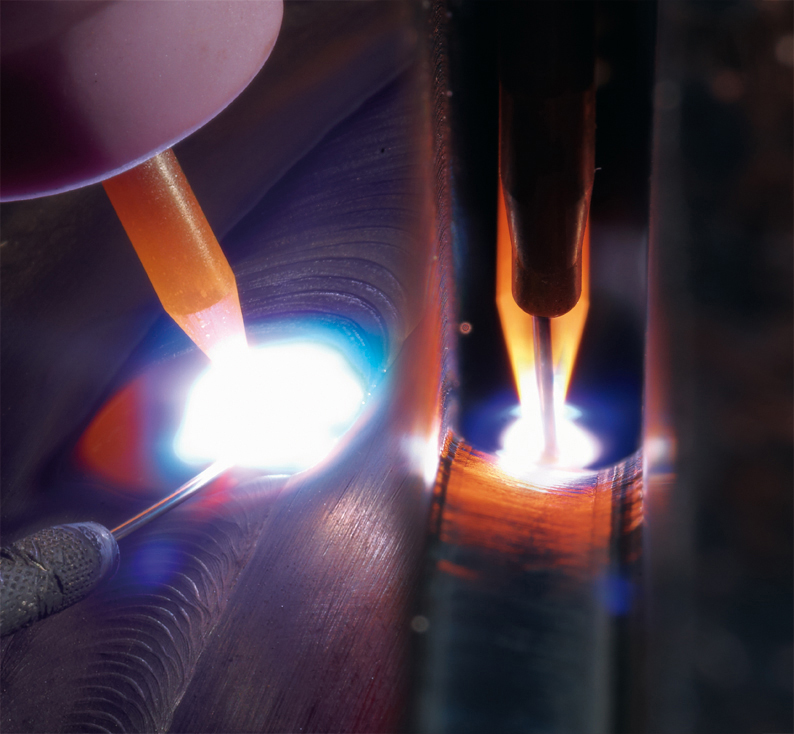

Tungsten Inert Gas welding (TIG), also referred to as gas-tungsten arc welding (GTAW), is a type of arc welding. It is also termed for the non-consumable tungsten electrode. You use this gas throughout the procedure. Although TIG welding is not the ideal solution for other businesses. Yet, it makes sense for us and those involving coil producers.

Welders almost primarily utilize it because of the high quality and standard it provides. The best TIG welder is extremely robust and, when done correctly, looks fantastic. Throughout this article, we’ll discuss the advantages of tig welding, and why we believe TIG welding is the ideal approach for what we are doing. As well as some of the compromises we considered before making our decision.

Advantages of TIG welding

Enhanced control

The tungsten electrode often used produces the electrical arc as one aspect of TIG welding which helps to improve control. Because of tungsten’s exceptional durability and melting temperature (3400°C), instead of employing a consumable electrode that melts into the welding. As with MIG or stick weld, the tungsten electrode warms and melts the filler metal which the operator feeds into the welding zone.

A foot pedal controls the amperage that supplies to the electrode. This part makes TIG welding unique from all other welding technologies, such as MIG welding. Where the arc current allocates at the predefined amount, termed as constant voltage. Because the voltage in a TIG welding system is changeable, it is one of the key areas where MIG welding varies from TIG welding.

The second portion of TIG welding which aids in controlling is the way of adding filler metal.

As previously stated, TIG weld uses a non-consumable electrode, which implies the filler material application and separates the heat steps. Thus, it allows the operator to have better control along with how much filler rod can be utilized. Unlike MIG welding, which only uses the gun for performing both tasks the electrode and the fills, TIG welding employs the gun for handling both the TIG electrode and the metal fillers.

Also read: How To Use Technology To Increase Workplace Efficiency

Flexible procedure:

For a range of factors, TIG welding is indeed a particularly versatile welding method. To begin with, the tungsten electrode & Argon (shielding gas) used in TIG welding could be utilized in practically all welding applications. Thus there is no need to switch out electrodes based on the work.

The best TIG welder is very adaptable when it comes to metals and alloy. You can use it for connecting joints. With a TIG welder, you can smoothly weld anything from super-austenitic stainless alloys likewise AL-6XN® to mild steel. It’s worth noting that the cost of filler rods will rise in tandem with the cost of base metal. Cheaper rod costs around $2-3/lb.as a good for most carbon steel metals, whereas filler is suitable with alloyed stainless steel including Hastelloy® or AL-6XN® which eventually pay you around $20 per pound or even more.

TIG welding is highly adaptable in terms of the places it may be used to weld. Use the TIG method to make overhead, vertical, horizontal, and even flat welds. Thus, we employ all four at Super Radiator on a daily basis.

The notion that filler metal isn’t always required adds to TIG welding’s adaptability. Materials may fuse without providing new material while keeping the structural qualities of the base material. This is due to the high temperatures achievable only with tungsten electrodes.

Welding doesn’t need to be cleaned after they’ve been welded.

When comparing TIG welding to certain other processes, it’s truly six of one or even half a dozen of the other welding. Cleanup is more like a plus point where TIG welding differs from many other welders. This gives ways for more advantage, because very few welding methods do not involve the one.

Since TIG welding is so fine, efficient and regulated. factors It doesn’t consider the other factors like sparks and spatter. Hence, TIG welds are somewhat ready to go after the welding is finished. Other welding procedures require post-weld scrubbing steps, which are considerably reduced or eliminated in this process.

Downsides of TIG welding:

The disadvantages of TIG welding come down to quality vs. quantity. Typically, the TIG method’s main drawbacks are its relative sluggishness and high expense.

Inadequate speed

There’s no denying that TIG welding is a slower procedure than other types of welding. If you want to produce a product as rapidly as possible, TIG welding is a big no-no procedure to utilize.

It might seem contradictory to employ a rather slow welding process during a production setting. Since we produce personalized products, we believe the degree of quality that TIG welding enables us to attain outweighs speed concerns.

TIG has a higher price tag

One aspect of this disadvantage relates to no. 1 reason, as the lengthier TIG welding process comes with a high opportunity cost. Again, it’s a matter of quantity vs. quality.